There is no substitute to the ‘in-depth understanding of the business requirements’, if you aspire to deliver a robust hardware design for your next IoT (Internet of Things) Project!

We will allow you some time to imbibe the following words of wisdom from our veteran and highly respected Hardware Design Expert – Mr. Raghavendra (Technical Manager, Embitel Technologies)

“In hardware designing, everything boils down to a clear understanding of the customer’s business requirement. You have to take care of the minute details of component and data specification and ensure that it corresponds to the final goal. You should not be selling him an elephant when he asked for a fish.”

He shared with us that before starting with hardware design of an IoT project, he makes sure that the team has all the answers for the following important hardware design considerations:

- What are the physical signals that need to be measured?

- How frequently we need to collect signals and how fast the data should be exchanged over the network?

- Should sensors be connected to the cloud directly or via gateway device?

- How much memory is required?

- And more!

This blog can serve as a ‘Hardware Design Guide’ for your IoT (Internet of Things) projects. Read along for more details!

-

Factors Critical to Hardware Design of IoT Sensor Nodes:

An IoT sensor node consists of sensor device, microcontroller, communication interfaces, power management module and other peripherals

Let’s discuss the critical hardware design decisions that you may have to take and factors that influence the design:

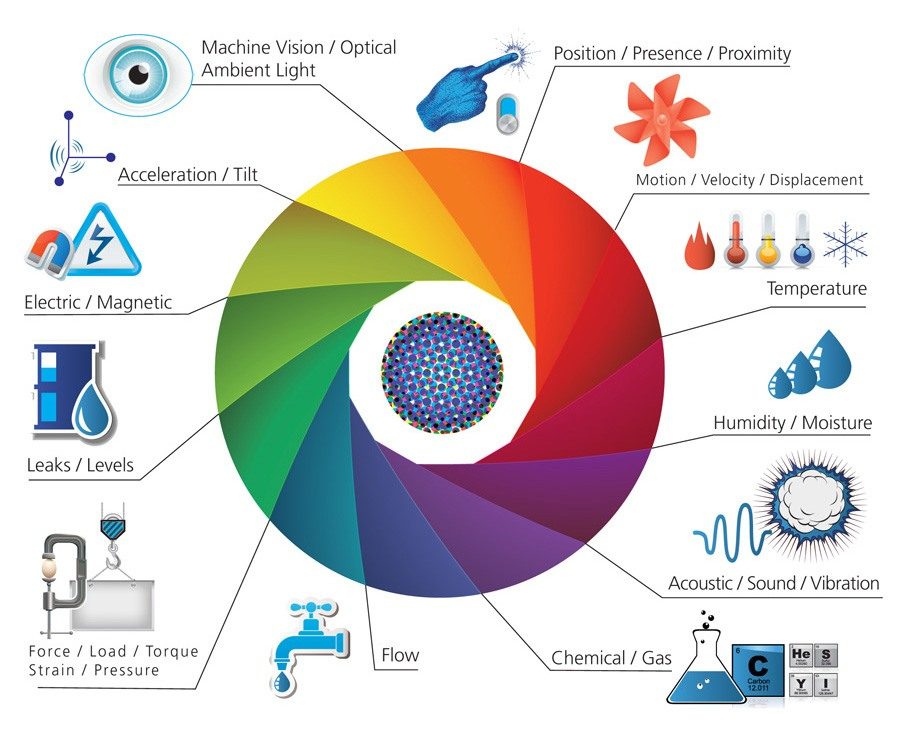

- First step is evaluation and selection of an appropriate sensor. Here are the factors/specifications that will have an influence on your decision

- IoT Sensor resolution: This determines the smallest measurement that a particular type of sensor can reliably detect.

– Type of sensors required: One can integrate either a digital or analog sensors in the hardware design. If you are using an analog sensor, you must also consider components for signal conditioning and signal processing in your design.

In such cases, the sensor circuit will also have to include either analogue-to-digital converter (ADC) or Sigma-Delta modulator.

- Sensor Nodes within an IoT network are expected to transmit 8 to 16 decimals of data in one millionth of second. And choosing a sensor with required data throughput is essential for efficient operations.

- Microcontrollers: The selection of industrial grade microcontroller is done after a careful evaluation of the business requirement (time and cost of project design) and functional factors that include:

- Algorithms: A microcontroller uses certain algorithm like ‘Random Number Generation’ algorithm to process sensor data into analog or digital format. So, you need to evaluate the algorithm supported by the particular microcontroller before choosing it.

- Security: Using a microcontroller with built-in hardware Crypto engines, such as Data Encryption Standard (DIS) and Advanced Encryption Standard (AES) engines, helps to ensure a secure transmission of data from sensor nodes to the IoT network.

- Power Consumption: Choosing low power microcontrollers helps in optimizing the overall power consumption. One can evaluate microcontrollers specifically designed for ultra-low-power applications, such as TI MSP430 or CC2650 wireless microcontroller.

- Communication Interfaces: Most of the IoT applications require sensors that use low-power wireless communication modems like NBIoT, LoRA, 4G LTE Cat-M1 for communication.

- Power management: The sensor nodes are designed to last for years. And this depends on the power source of the sensor nodes. One can choose low power batteries such as CR2032 lithium-ion coin-cell battery, as it outputs a constant voltage, is low-cost and offers a battery life of greater than 10 years.

Additionally, one may integrate nano-timer such as TPL5110 to optimize the power consumption, as the sensor nodes switch between wake-up and sleep modes.

Image: IoT sensors used today are numerous in types ; Source:IoTOne

An IoT gateway could either be a simple gateway device that executes core functions such as protocol compatibility and device management; or an Advanced edge gateway devices with additional data analytical capabilities.

Designing an IoT gateway hardware would thus depend largely on the type of functions it is expected to perform.

Here is a glimpse of some common hardware design parameters that will influence your IoT gateway development

- Microcontoller v/s Microprocessor: An IoT Gateway with microcontroller is ideal for small to a medium scale application, while you may need a gateway with a processor, if the gateway has to perform more complex functions such as data analysis and storage.

- Power Consumption: This will depend on the complexity of your IoT hardware & power requirements of other components of the circuit. For example, if your design consist of a number of external devices such as display screens, camera – the overall power consumption might go up.

- Energy from renewable sources: If your device is being powered by renewable energy sources like solar, your design will have additional components. For example, you would need as 2 stage solar converters ( MPPT based converters and DC –DC/DC-AC converters), power management ICs that are compatible to the solar panels to sufficiently charge your devices.

- Processing Power & OS: This becomes a critical factor if you are deploying Gateway with Edge Analytics capabilities. This is because for data processing, IoT Gateway design should include necessary amount of memory, and a multi-core processor. The OS chosen should have a higher context switching rate and real-time response rate.

- Memory : Most of the gateway devices used in critical IoT systems such industrial automation, fleet management are based on hard real-time controllers and hard real-time schedulers. In such cases , data is stored in RAM memory. Other memory types used in a smart IoT gateway device would include NOR Flash, Flash boot .

As mentioned before, the memory requirement in the design increases, if the IoT gateway device is expected to perform processing and data analytics.

- Communication/ Networking Modules:

Within an IoT network, devices or systems ( sensor, gateway, end devices) can communicate either through a Wireless ( Bluetooth, Wi-Fi, Cellular) communication channel or a Wired Connection. Your IoT design will have to include Wireless communication modules when when the devices/systems are located in close proximity and there is little scope for setting up hardware installations required by a wired connection. (installing Ethernet cables, routers etc.) .Communication Interface Type of Wireless Communication Sensor/Device to Gateway Cellular(4G), NBIoT, ZigBee, Bluetooth Device to Cloud WiFi, Cellular(4G), 6LowPan, LoRa A wired communication is usually deployed for long range communications. Ethernet, with an average speed of 10 Mbps, is one of the most used wired communication protocol for connecting devices for applications like industrial automation.

Fast Ethernet (IEEE 802.3u) and Gigabit Ethernet(IEEE 802.3z) with transmission speeds of 100Mbps and 1000Mbps are some of the widely deployed wired connection interfaces.

Many of the standard IoT hardware boards such as Raspberry Pi, Arduino, Beagle Bone are embedded with a set of communication interfaces ( UART, USB, Bluetooth , Wi-Fi, Ethernet port). You can also create a custom hardware board wherein you include only the selected communication interfaces that your project needs.

Hope you liked this blog. If you are looking for a more detailed and personalized support for IoT project design, please get in touch with our product engineering experts.