Safety Analysis Activities (FMEA, FMEDA, DFA, FTA) For ISO 26262 Compliant Solution Development

As part of ISO 26262 services, we help our customers with a wide range of safety analysis activities like HARA, FMEA, FMEDA, DFA, FTA, FMECA and more.

Our team of ISO 26262 experts and automotive domain veterans have partnered with global Automotive OEMs and Suppliers to deliver cutting-edge solutions for lighting system, electronic power steering, Seating Control, Powertrain ECU and so on.

We provide support for safety analysis activities across the safety lifecycle- Concept, Systems, Hardware and Software.

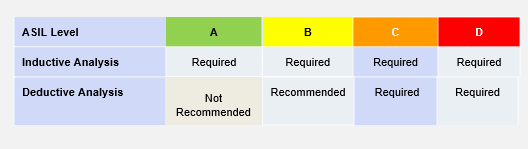

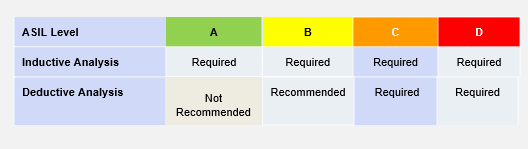

- It is a bottom up approach where engineers first consider a fault in a component and then analysis the effects

- Failure Mode and Effects Analysis (FMEA) is an example of inductive analysis

- Inductive Analysis is recommended for all ASIL Levels (ASIL A to ASIL D)

- It is a top down approach where a system failure is identified followed by the component and its state that led to the failure

- Fault Tree Analysis (FTA) is an example of deductive analysis

- Recommended for ASIL B and required for ASIL C and ASIL D

- Analysis based on qualitative aspects of failure performed by individual experience and past history of faults

- Examples are FMEA and DFA (Dependent Failure Analysis)

- Involves certain metrics such as Single Point Failure Metrics, Latent Failure Metrics and PMHF for estimating failure rates

- FMEDA and Quantitative FT are commonly used Quantitative Analyses

A Snapshot of Our ISO 26262 Compliant Safety Analysis Services

Concept Phase

- Support for Impact Analysis for change evaluation for a system

- Hazard Analysis and Risk Assessment (HARA)

- Hazard and Operability Analysis (HAZOP) as part of HARA or a standalone analysis

- Gap Analysis for existing solution

System Phase and Support

- System FMEA (Failure Mode and Effects Analysis)

- Fault Tree Analysis (FTA) specific to the system phase

- Support for Process FMEA

Software Development Phase

- Support for Software Design FMEA and DFA (Dependent Failure Analysis)

- Static and Dynamic Code Analysis

- Model-in-Loop (MIL) and Software-in-Loop (SIL) testing as per ISO 26262

- Expertise in tools like QAC, Polyspace, LDRA, CANTATA, Tessy Tool and more

Hardware Development

- Hardware Design FMEA

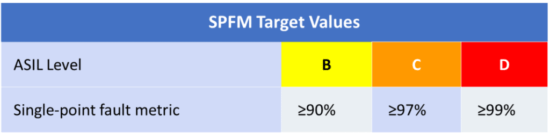

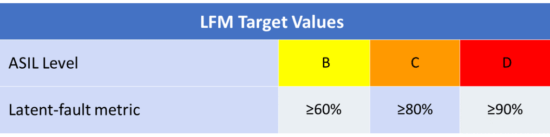

- Failure Mode, Effects and Diagnostic Analysis (FMEDA) for deriving architectural metrics (SPFM, LFM, PMHF)

- Support for Quantitative FTA, Dependent Failure Analysis (DFA)

- Failure Modes, Effects and Criticality Analysis (FMECA)

- Hardware Design Simulation using ISO 26262 Qualified Tools such as Cadence and Mentor Graphics

Hardware Metrics Target as per ASIL Grade

Expertise in ISO 26262 Qualified Tools for Safety Analyses

- ISO26262 qualified Safety Analysis tools: SOX, APIS, Medini Analyze, Exida

- ISO26262 qualified Code Analysis tools: QAC+, Polyspace, Tessy, LDRA, RTRT, CanTATA, MxSuite

- ISO26262 qualified HW analysis tools: Cadence, Mentorgraphics