ISO 26262 Compliant LIN Protocol Software

ASIL D ready LIN protocol software to power ECU communication for safety-critical components

Enabling Low-Cost ECU Communication

LIN protocol software offers low-cost ECU communication where versatility and high bandwidth of CAN protocol is not required. LIN Bus protocol also serves as a sub network to CAN thereby reducing the amount of harness and thus achieves low-cost and ease of implementation.

Embitel’s LIN Protocol Software

Embitel offers a ready-to-deploy LIN protocol software package. Our LIN stack is compliant to LIN 2.0, LIN 2.1, LIN 2.2, ISO17987 and SAE2602 standards. With our production-grade LIN stack, you can implement customized LIN Master and LIN Slave solutions.

Our LIN protocol stack is ASIL D ready! It can be deployed for ASIL D grade automotive solutions to enable highest level of functional safety.

We offer this LIN Protocol stack under a one-time licensing fee model. This engagement model makes the LIN stack highly beneficial for our customers.

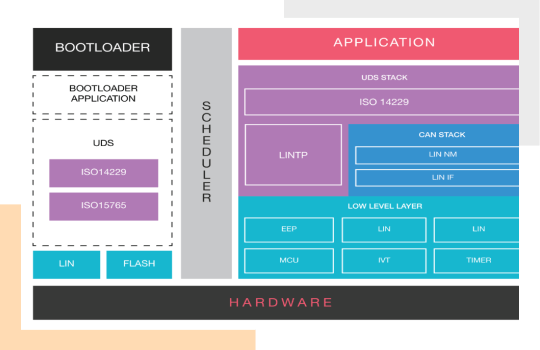

LIN BUS Protocol Stack: Details of the Software Architecture

- LIN Device Drivers: It facilitates the access to the hardware resources and offers a hardware independent API to the upper layer. We develop LIN driver for the specific microcontroller as per the safety requirements of the customer.

- LIN Hardware Abstraction Layer: Consists of LIN Interface and LIN TP Layer; Responsible for hardware abstraction, error handling and transport layer software services for diagnostics.

- LIN Network Management: Coordinates the transition between normal operation and bus-sleep mode of the network.

Features of Our LIN Protocol Stack Solution

ASIL D Ready

- LIN network management (LIN NM) and interface layer (LIN IF) have been developed as per ISO 26262 guidelines following ASIL D recommendations.

- Our LIN protocol stack can be integrated to ASIL D category ECU development programs.

LIN Stack License Model

- We offer our industry recognized LIN protocol software under a one-time licensing fee model.

- Terms & conditions regarding IP rights and source code ownership are completely transparent and fully aligned with the customer’s requirements and vision.

LIN Master / Slave Architecture

- The LIN subnet is based on a master-slave architecture and we have partnered with our customers to deliver a customized LIN Master and LIN Slave solutions.

- Within the In-Vehicle Network, LIN Master is integrated with Master ECU (which is part of Body Control Module).

- LIN Master ensures robust communication and control of the LIN Slave nodes

LDF to auto-code generator Tool

- MISRA C compliant auto-code generation for LIN Interface configuration in lesser time as compared to manual method (3-4 week)

- This saving in efforts translates into reduction time-to-market and thus development cost.

LIN Protocol Stack Use-Cases

- LIN protocol stack implementation for sun-roof systems, DC DC converter, wiper, power-window etc.

- LIN protocol based ECU re-programming (Bootloader) over UDS.

- Integration of UDS over LIN TP.

LIN Bus Protocol Stack Integration, Configuration and Testing Service Offerings

Development and Integration of LIN Driver

- Device Drivers development for the LIN Slave microcontroller

- Device Drivers development for LIN Master microcontroller

- Reusable device drivers to ensure reduced development time and cost

- Support for driver integration for most MCU families

Node Configuration, LIN Network Management and LIN TP Configuration

- Support for Static and Dynamic Configuration of Nodes (ECUs)

- Already integrated Read/write to the stack function

- Sleep/Wake up functionality for the nodes

- Support for segmentation of large data packets over LIN TP

Development and Configuration of LIN Master

- Configuration of the Scheduler Table based on SWRS and LDF files

- Support for Unconditional, Event, Sporadic and Diagnostics frame

- Skeleton code for Scheduler Table

- Integration with the end-user application and HAL

- Algorithm development for Scheduler Table

LIN Bus Protocol Stack Support and Maintenance Services

- Documentation Support: Low-level design and High-level design documents

- LIN conformance test using Vector Tools. This ensures robustness of Data Link Layer

- Unit, Integration and Functional testing services

- Support for MISRA C Report creation

Development and Configuration of LIN Hardware Abstraction Layer

- Tx and Rx message configuration from LIN Description File (LDF)

- Support for both tool based and manual configuration

- Proprietary LDF to auto-code generation tool

- Configuration for Software Filtering

- Vector tool based LDF generation from excel sheet

- Configurable HAL standard code is part of the stack package

Support for upgradation to LIN 2.2

- Evaluation of existing LIN network to analyze limitations, compatibility and other issues that need to be addressed

- Support for new network design or changes in existing LIN network based on the analysis.

- Integration of LIN 2.2 by updating the previous version of LIN protocol

- Support for thorough testing and validation of the network after integration of LIN 2.2 protocol to ensure performance and reliability of the nodes.

ISO 26262 Compliant with ASIL D Level Safety

- LIN TP, LIN NM, LIN interface layer and LIN Node service layers are ASIL D ready

- Safety guidelines and methodologies enlisted in Part-6 of ISO 26262 standard (Table-1 to 15) are rigorously followed.

- E2E profiles and CRC library are implemented for data integrity

200+

customers supported since 2010

100+

scalable and reusable Bootloader platforms delivered

30%

quicker time-to-market enabled

95%

lesser development time with PC-based automation tools

Embitel’s Advantage

ISO 26262 Compliance

We have developed our LIN protocol as an SEooC (Safety element out of context). The development process follows ISO 26262 guidelines mandated for SEooC development.

Industry-wide Recognition

We have integrated LIN stack for several production programs across the globe. The extensive experience gives us an edge in the implementation of on-board diagnostics for automotive use-cases.

CMMi Level 3 Certified

As a CMMI level 3 certified organization, we have a robust process model in place. This ensures that the LIN stack along with other stacks are reliable, bug-free and efficient.

Configuration & Integration Support

Our LIN protocol software is designed to be fully configurable as per project specifications. We provide support for configuration of LIN Stack based on LDF.

Support for After-market Solutions

Development, testing and maintenance support for after-Market Products for Telematics, ADAS, remote vehicle diagnostic applications.

ISO 26262 Compliance

We have developed our LIN protocol as an SEooC (Safety element out of context). The development process follows ISO 26262 guidelines mandated for SEooC development.

Know more about our LIN protocol software business model, features, use-cases, and technical specifications.

FAQs About LIN BUS Protocol Stack Solution

Knowledge bytes

What is Local Interconnect Network (LIN) BUS Protocol Stack?

LIN protocol is a sub-network deployed in both passenger and off-road vehicles. Unlike CAN, which is a broadcast protocol, LIN is a master/slave communication standard.

Simpler functionalities like wiper, mirror control and washer etc. are usually handled by LIN network.

The LIN master ECU is integrated with the body control module, from where it initiates the command. The LIN master nodes will receive the command over LIN network and act accordingly.

LIN Slave nodes don’t communicate with other networks, unless initiated by the LIN master.

What makes Local Interconnect Network (LIN) important when CAN already handles in-vehicle networking?

Adding too many nodes (ECUs) to the network causes Network BUS slow down. To prevent this, a LIN sub-network is designed. The body control module usually acts as a gateway between the main network (CAN Bus) and the subnets (LIN Bus)

LIN Bus is a single wire network best suited for small applications like wiper and washer etc. Using CAN for such application lead to increase in the software and hardware cost.

What are the advantages of upgrading your vehicle network solutions to LIN 2.2?

LIN 2.2 is the latest version of LIN bus protocol released in 2010. It is also the most implemented version of LIN protocol as it has several advantages compared to its previous versions.

LIN 2.2 offers several advantages over previous versions of the LIN protocol, including:

Increased speed: LIN 2.2 operates at a maximum speed of 20 kbps, which is twice as fast as the previous LIN 2.0 and 2.1 versions.

Improved scalability: LIN 2.2 supports up to 16 slave nodes on a network, which is four times the number of slave nodes supported by previous versions of the protocol.

Enhanced reliability: LIN 2.2 introduces improved error detection and correction mechanisms, which help to ensure reliable data transmission even in noisy environments.

More robust network management: The LIN 2.2 protocol includes several new features for network management, such as improved wakeup functionality and support for network synchronization.

Lower power consumption: The LIN 2.2 protocol includes several new features for reducing power consumption, including a sleep mode for slave nodes and reduced idle current consumption.

How to build an ISO 26262 compliant LIN protocol stack which is ASIL D ready?

The idea to develop a LIN protocol stack as per ISO 26262 is essentially building a safety element out of context (SEOOC). In such a scenario, the safety requirements, safety goals etc. are not determined through HARA, instead they are assumed at component level.

These assumed safety requirements should be aligned with typical safety goals for LIN communication in automotive systems. Part-6 of ISO 26262 standard gives a detailed guideline along with testing and coding methodologies to be implemented. Since, the target is to develop an ASIL D LIN protocol stack, all these guidelines summarized in close to 15 tables must be followed rigorously.

In addition, E2E profiles are implemented to ensure data integrity and reliability during communication.