IoT Sensor Node Development-Services

IoT Sensor Node Development: The Best Practices

The scale and complexity of the IP-based IoT sensor node network depends on the automation use-case. IoT sensors are always associated with a unique design challenge – operating conditions do not facilitate wiring or any external power source.

The following are some best practices to overcome this challenge and ensure successful IoT implementation:

Power Management: Key to Success

- Internal battery is the only power source and IoT sensor nodes are expected to run for years without battery replacement

- Implement wake time to collect data, else go maintain sleep mode to save power

- Complexity of power management techniques depends on the IoT application

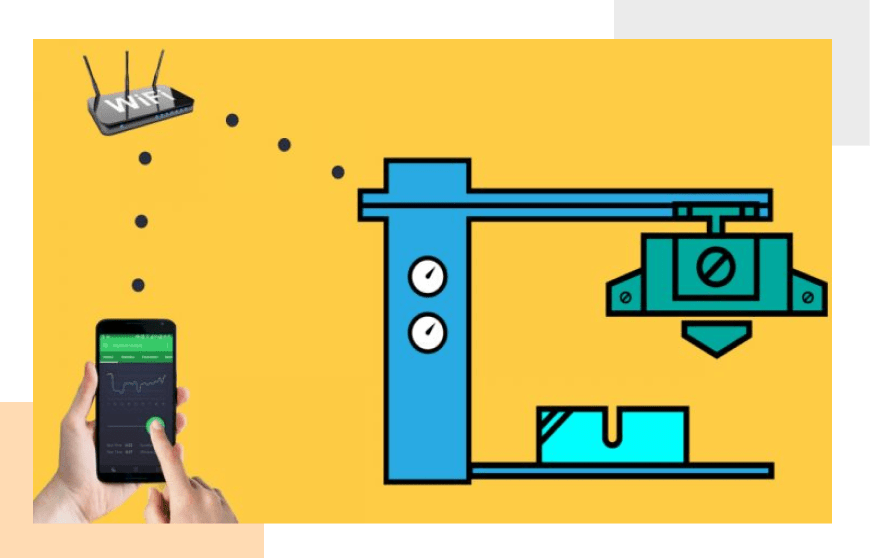

FOTA (Firmware Over The Air) upgrade

- Field deployed IoT sensor node should support FOTA software upgrade

- This ensures that IoT sensors are updated with latest security patches, OS and new feature releases

- This has direct impact on IoT sensor node security and performance

Optimize Network Design and Data Transfer

- Analyze project requirements and deploy IoT sensors using best-suited network topology – Point-to-point, Star, Mesh and more

- Based on the application, IoT developers should design and configure the Sensor network for Time-based or Trigger-based data gathering and reporting from IoT Sensors

IoT Sensor Development Services

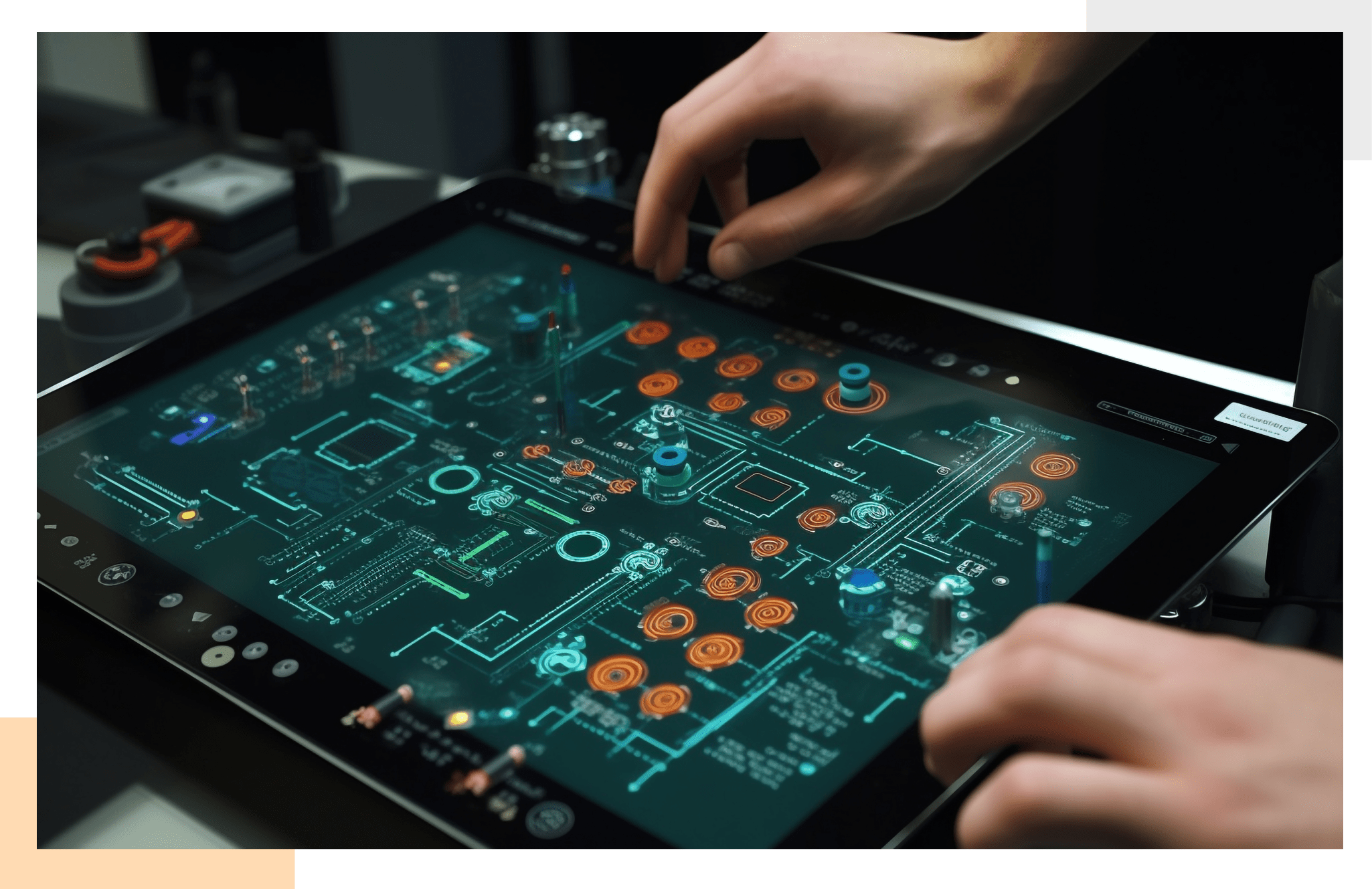

IoT Sensor Node Hardware Design Services

- Requirement gathering and system analysis workshops with our IoT Consultants

- Architecture design and BOM cost optimization

- Schematic and Layout designing

- Signal Integrity Testing, Prototyping and Production support

- POC development based on off- the-shelf Evaluation boards.

IoT Sensor Node Software Development and Testing Services

- Development of IoT sensor node software for custom hardware

- Support for different communication protocols - Zigbee, Bluetooth, EnOcean, LoRA, Z-wave, 6lowpan and Wi-Fi

- Data storage and handling in case of gateway connectivity issues

- Ranging and connectivity testing of IoT sensor nodes with IoT Gateway

IoT Sensor Node Maintenance and Support Services

- End-to-end field support, maintenance and OTA upgrade

- Support for field testing and deployment

- Data collection, analysis, and performance tuning

- Bug fixing and support in making the production software more stable

FAQs Regarding IoT Sensor Node Development

- A power-efficient design enabled by integration of low power-consuming components such as nano-controllers, low power regulators and more. These hardware components are programmed to ensure low current consumption, when the nodes are in off-state.

- Compact form factor, which is optimized to justify the critical business requirements of performance, power and cost.

- Optimal beacon rate configuration, that is in line with requirements of low energy consumption, high-speed and frequency of data transmission.

- Longer battery life, which is also ensured through energy-efficient design of the sensor nodes.

Security is an integral part of our solution development process and is addressed at three levels; viz; data, device and the network.

Data Security: The microcontrollers integrated in the IoT sensor node design consist of specific embedded encryption & decryption engines that adhere to the DES (data encryption standard) and AES (advanced encryption standard).

Device security at hardware level: The sensor node hardware is integrated with TPM ( Trusted Platform Module) to protect the sensor node against security threats including hacking or cloning.

Network Security: In order to protect the network against security threats, each and every data exchange between the sensor node and the devices is secured using SSL encryption mechanism.

- Requirement Analysis: In-depth analysis of requirements and design considerations that includes battery design, evaluation and selection of industrial sensors, operating environment, product casing and more.

- Software Design: Software Code optimization for speed of operations and efficiency in data collection

- Hardware design: Hardware design architecture and component selection to ensure longer battery life, and low power consumption.

Yes. There are two approaches to extend the range of sensor communication:

- Sensor nodes can be integrated with smart antenna technology with higher gain in order to extend the network strength. Whip antenna would serve as an ideal example of antenna with an improved gain.

- Software configuration of RF ( Radio-Frequency) registers to enhance the maximum power/gain levels of the antenna. This is also an ideal method to enhance the range of sensor communication.We can help you in strengthening the range of sensor communication using either of the two approaches mentioned above. Based on your business use-case, the best suited approach will be executed.

This question can be answered only after we get a thorough understanding of your industrial IoT system. We will do a detailed analysis of your existing industrial set up and design a solution that is suitable for your use-case. This will include:

- Design and selection of hardware components,

- Analysis & design of communication interfaces between sensor -device and sensor-IoT gateway that are a best fit for your IoT use case

We can support the development of intelligent sensor nodes that can process raw data at the node itself. Having said that, sensor nodes are ideally designed as low-power devices, having functionality limited to aggregation of crucial field data. Development of sensor nodes with in-built intelligence requires additional processing power, memory and integration of software algorithms that will subsequently add to the development cost as well.

Development of ultra-low power sensor nodes should address following considerations:

- Focus on power-efficiency throughout the product design thinking – right from architecture design, software development to the sensor node integration with the target application/system.

- Careful selection and management of source of power supply for your sensor nodes.

- The complete design should be robust and power-efficient.

- Software code should be highly optimized for time as well as energy efficiency.

- Should include low-power hardware components including microcontrollers, capacitors, timers – to name a few.

- A careful calculation of sleep and wakeup phases of the Sensor nodes, to determine how well they leverage the battery power. This is a crucial factor in ensuring minimal power consumption.

IoT sensor node solution has a comprehensive design that can be integrated with a wide range of IoT specific communication protocols including MQTT, 6 Lowpan- among others.

In order to ensure business continuity even when the sensor node loses connection with the IoT network, we have a data back-up strategy in place. Under this technique, the sensor data will be stored temporarily in local memory. Once the connection with the IoT network is re-established, this stored data will be pushed to the cloud backend. Note: But adding such a memory module will lead to added development cost and reduction in the overall battery life.

Our IoT sensor node development team comprises of:

- IoT Architects and developers

- Hardware Engineers

- Network design Engineers

- Embedded Firmware developers

- Embedded engineers with hands-on experience in IoT communication protocols ( MQTT, CoAP, HTTPS)

IoT in Action: Success Stories

Related Blog: Learn More about IoT Gateway Development

Knowledge bytes

What role does a Sensor play in an IoT Network/System?

In an IoT system, sensors are responsible for capturing changes in various physical parameters, related to the operating conditions or deployed devices. IoT Sensors then convert this captured information into electrical signals. This can involve detection of fluctuations in external conditions such as pressure, temperature, moisture, vibration, voltage and current, velocity & many more. Millions of sensors are used as reliable tools for data aggregation and transmission across a range of industries. For example , in the manufacturing – for monitoring the production processes, in defence – for collecting mission critical information about ground stations and vehicles , in retail – for real-time tracking of shipment goods ; to name a few. Learn about some common types of sensors used in Industrial automation systems: 7 Most Commonly Used Sensors for Developing Industrial IoT Solutions

How can one evaluate Sensors for an IoT Project?

Before selecting sensors for your IoT projects, you must look for the following sensor specifications,

Resolution:It is the smallest measurement a sensor can

detect and is

usually expressed in bits( digital sensors) . A temperature sensor with a resolution of

0.125 °C will give a digital output with step size of 0.125 °C.

Step size refers to

difference in voltages between two consecutive digital level (i.e. 0001 and the next level-

0010 or 0000).

Sensitivity: It is the smallest absolute amount of change detected by a sensor. The sensitivity of a sensor is a measure of change in sensor output with respect changes in the inputs measurements. A thermometer with a sensitivity of 1 cm/°C indicates mercury moves 1 cm for every 1 °C change in the temperature.

Range: Range specifies the maximum and minimum values of the input, within which a sensor can operate reliably. Outside of the specified range, sensor would most often will either not give any output or will get damaged.

Accuracy: Accuracy is the absolute difference between the sensor output and the true/actual value of the property being measured. In other words, accuracy specifies the maximum error that can happen in the sensor readings.

Precision:Precision is a measure of a sensor’s capability to give same output readings when provided with the same input, multiple times.Step size refers to difference in voltages between two consecutive digital level (i.e. 0001 and the next level- 0010 or 0000)