In this Part II of the IoT Hardware Design series, our focus will be on other significant design factors such as Security, FOTA , and Compliance Certifications.

“Also read: Hardware Design Guide for IoT Projects (Part I): IoT Sensor Nodes and Gateway Devices”

Let us dive deep into them!

-

IoT Hardware Design for Security:

Your IoT project design must include robust security mechanisms to safeguard the IoT system and data, from any unauthorized access and other security threats like IP theft, malware attacks and more.

Let us look at some of the common hardware security mechanisms in practice today:

- Root of Trust: A Root of Trust (RoT) is a set of functions (software codes) that are hardened into a hardware module like Hardware Security Module (HSM). This stores the keys to encrypt and decrypt data, and create digital signatures.

- PUF for Data Security: Data security can be ensured through public and private key mechanism. In order to ensure that these keys are generated from a secure source, you can select hardware devices with a Physically Unclonable Function (PUF).Under the PUF scheme, a unique key is generated depending on the unique properties of each piece of silicon.

- Board level and chip level security measures help to protect the devices against tampering, IP theft, reverse engineering attacks etc.

- Hardware security against Differential Power Analysis ( DPA) attacks: Often electronic devices are prone to DPA attacks, whereby a hacker can calculate the power consumption of any hardware device to extract cryptographic keys from the device.

Using hardware devices with DPA licensed countermeasures in your IoT project is a foolproof method to ensure high-end security of your devices.

Image Source: iStock -

FOTA for Remote Device Management:

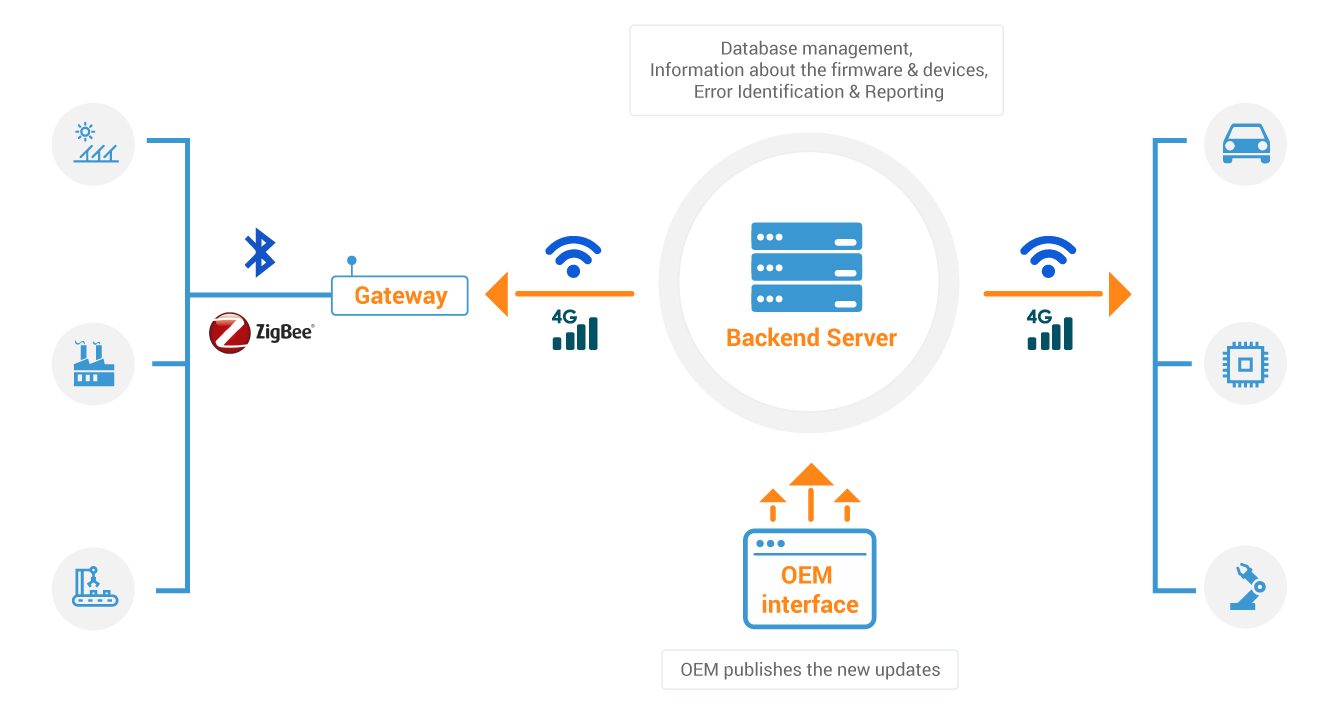

In IoT systems, Firmware Over-The-Air (OTA) is a popular technique for remote and reliable management of field devices and applications.

You can enable Firmware Over-The-Air (OTA) update in IoT devices either by designing a customized FOTA module from scratch or use any of the managed platform solution for OTA firmware systems

- In a custom built FOTA solution, you can plan the scheduling, release, recovery, reporting of firmware images; manage the firmware versions; choose the hardware, device interfaces and software for enabling FOTA- based on project requirements and BOM costs..

- The managed platform based solution comes with in-built hardware , software tools, and takes care of system firmware, device grouping, event logging – among others.

Also read: The process details of the FOTA update installation onto the target devices.

-

Regulatory Compliance & Certifications:

The rush to meet the functional requirements combined with the pressure for reducing the time to market , most often, leads the project development team to overlook the compliance and certification regulations.

However innovative your application might be, if it doesn’t meet the certification and compliance regulatory requirements, it is not destined to see the light of day.

The Product certification and regulatory compliance process must be an integral part of the IoT hardware design phase. You must check that each of the component you pick for your IoT design meets the essential regulatory standards and certifications such as Restriction of Hazardous Substances (RoHS) Directive, Federal Communications Commission’s (FCC) regulations, EMC/EMI compliance – to name a few.

-

Choosing Hardware for Prototype vs Production:

Selecting hardware for prototype development is altogether different from choosing hardware for production. The objective of the prototype development usually is to demonstrate the most essential and viable functions.

On the contrary, at the production stage your focus is on factors like future scalability, ease of integration, tolerance to extreme environment conditions, hardware warranty , BOM cost– to name a few.

A clear definition of prototype and production goals before the IoT hardware design stage will help you make a wise selection of components for IoT sensor nodes and IoT gateway.

At the prototype stage , you can go for off-the shelf hardware platforms with added features like breadboard-able headers, USB connectivity, onboard antenna.

For example, Particle’s Electron is an Arduino-compatible microcontroller with an integrated cellular modem and can be used for faster prototype production.

And based on the prototype evaluation and business estimates, you can for an off-the shelf hardware boards & components or custom designed ones or have a mix of both.

Hope you liked this blog series on IoT hardware design considerations. If you are looking for a detailed support for IoT project design, contact our product engineering experts.