About the Customer:

Our customer is an automotive tier-1 supplier specializing in developing microcontroller-based automotive solutions. With innovation embedded deeply in their products, they wish to create safer, greener and more comfortable mobility.

Business Challenges:

The emergence of LED (Light-Emitting Diode) technology has had a significant impact on automotive lighting. In terms of efficiency, longevity, design flexibility, adaptive capabilities and diverse use-cases, LED lighting has been a game changer.

Since our customer has been at the forefront of semiconductor-based innovations in the automotive domain, they wished to extend this to automotive lighting solutions as well. Their team was keen on developing an ASPICE compliant RGBW (Red Green Blue White) LED solution that can be customized as per the end-customer’s requirements.

An automotive grade solution is required to adhere to certain automotive standards such as MISRA C 2012, HIS Matrix etc. The customer’s software team faced certain challenges in following such automotive standards and coding practices specific to the automotive domain.

Following the ASPICE process came across as another challenge as it required ASPICE compliance at an organization level. Since most OEMs now require ASPICE compliance, our customer was looking for a partner with expertise in ASPICE level 2 compliance. We met all such requirements of the customer, and the seed of a new partnership was sown.

The customer’s team performed the system analysis and came up with a set of system requirements. These requirements were the foundation for us to develop the intended LED automotive lighting solution.

Embitel’s Solution:

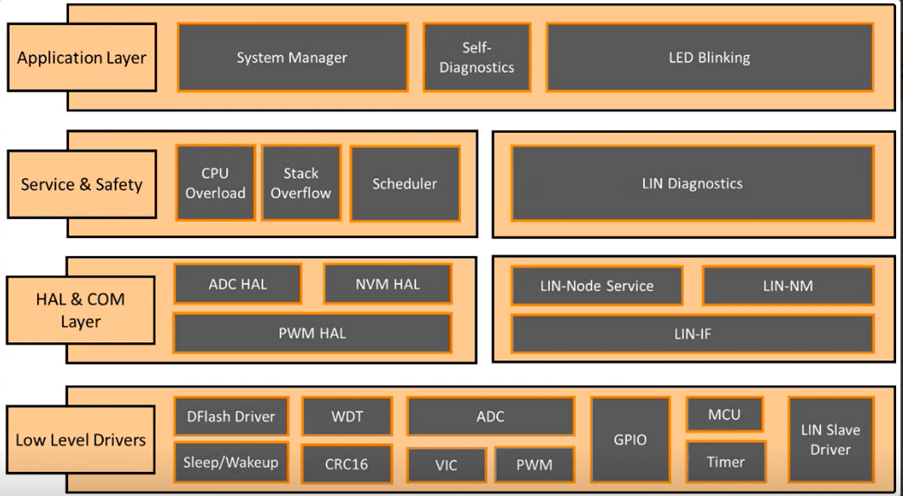

In a nutshell, our task was to build a base software (BSW) with all the components required for LIN-based control of the RGBW LED using a PWM generator. In addition to the PWM generator, there were several other components required for the lighting solution to work in the intended manner.

Our LED-based automotive lighting solution involved the development of the base software, incorporating key components such as ADC, VIC, watchdog timer, sleep/wakeup, and GPIO. These components were carefully integrated to ensure efficient and reliable functioning.

The Hardware Abstraction Layer (HAL) was utilized to provide a standardized interface between the software and hardware, enabling seamless interaction with the microcontroller and peripheral devices. A scheduler was implemented to manage tasks and optimize resource allocation, ensuring efficient execution of software functions.

One of the major highlights of our project was the integration of LIN-based control for LED lighting using a PWM generator. Through LIN frames, the duty cycle of the PWM can be changed, enabling precise control over the LED lights. This functionality allows for dynamic adjustments, facilitating various lighting effects, brightness levels, and customized lighting patterns.

In addition to the base software, we developed applications to showcase the capabilities of our LED-based lighting solution. An example is the LED blinking application, which demonstrates the functionality of our solution by controlling the LED’s on/off states.

To facilitate the configuration of various components of the solution, we have provided a comprehensive user manual. The manual guides customers through essential configurations, such as PWM generator and driver configuration, output current configuration, duty cycle configuration, and more. This documentation ensures that customers can easily adapt the solution to their specific needs, enhancing usability and flexibility.

Additionally, we have extended support to customers in aligning and integrating their LIN node services within our architecture, enabling seamless integration and full utilization of our LED-based lighting solution.

Throughout the development process, we adhered to ASPICE guidelines to ensure high-quality software. Our dedicated ASPICE team was actively involved in the development and testing phases (SW 1 to SW 6) conducting module testing, integration testing, and qualification testing (white box and black box). Regular audits, including work product audits and process audits, were performed to verify compliance with the correct processes.

Embitel’s Impact:

Through our ASPICE competence and deep understanding of automotive lighting domain, we were able to grasp the requirements very well. And that translated into a robust solution with all bugs and error contained at the right stage.

We also developed unique test cases that helped make the solution even more robust and reliable.

Tools and Techniques:

IAR Workbench: Code development and debugging, Compilation and Flashing of software

Evaluation kit: Base for testing the solution

Unit Testing: Tessy tool

Polyspace: MISRA C check and static analysis